What is a House?

Two years after their iconic Eames House, Charles and Ray designed a low-cost, prefabricated house for series production: the Eames Modular House. The concept was intended to allow postwar families to live in a modern home for an affordable price. The Eameses proposed a one-story wooden house with an open plan interior, a curved roof, and exposed beams. The architectural concept was executed into detailed plans and models for a prototype house which, unfortunately, was never built.

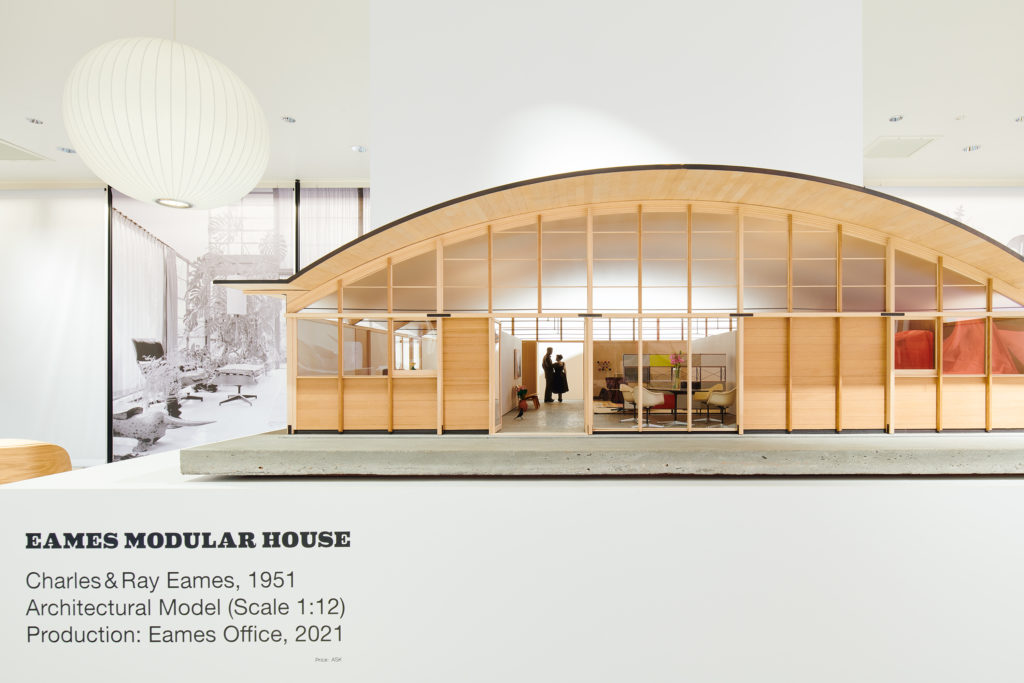

Now, 70 years later, a new architectural model at 1:12 scale recontextualizes this pioneering mid-century effort towards prefabricated housing in a contemporary setting. The model offers the tantalizing possibility of what could be if this never-built Eames design were to be added to today’s architectural landscape.

Charles and Ray Eames’ often-stated objective, “We want to make the best for the most for the least.” defines how mass production was always central to their thinking. Ray said, “Anyone making one thing—that’s very nice, to make one thing. But to be able to keep the quality in mass production is the only reason we’ve been working so hard. Because we could easily turn out a nice thing, and another, and another. But to figure a way that the hundredth, and the five hundredth, and the thousandth would have the original character…” They worked this way not just with furniture—their molded plywood chairs and molded plastic chairs defined the post-war world – but also with architecture, and specifically housing.

Two charts drawn by Charles and published in Arts & Architecture Magazine in 1944 explained why the Eameses answered the question “What is a House” in terms of factory-produced housing:

“It has been estimated that one million five hundred thousand houses each year for a period of ten years will be needed to relieve the urgent housing problem of this country alone. In the world at large, fifty million families will be in need of shelter as the result of war. The enormity of such a need cannot even be partially satisfied by building techniques as we have known and used them in the past. Large scale industry would seem to be the only logical means by which we can achieve an enterprise of such proportion.”

Charles and Ray Eames

The 1944 house charts do not concern themselves with aesthetics. Charles and Ray Eames were confident, from their observations of nature and of historic designs, that what works best, is what looks best. In the case of the houses they had in mind, there were two important threads. First, the needs of those who would live in it, for which “an understanding of family behavior” was required. Charles and Ray had a very broad view of human needs and recognized that these could be emotional and spiritual and physical. Second, a “vocabulary of materials and techniques,” not to make a style statement, and with no preconceived ideas about what materials and techniques should be used, but instead, specific materials and techniques that best meet the needs of the individuals and families who would call the house their home. Charles and Ray didn’t believe that buildings should be costly to build, nor should the buildings impose demands on the users by requiring constant maintenance, and repair, and upkeep.

They first applied these principles of practical, mass-produced housing to their own home, the Eames House. This was built as part of the Case Study House program (1945 to 1966), which invited architects to design residential buildings that allowed postwar families a “modern” way of living while keeping prices, use of material and construction time as low as possible. Their own house, Case Study House Number 8, remained a one-off only because in 1949, when it was built, the kind of factory-produced housing components which Charles and Ray anticipated in 1944, didn’t yet exist. However, they were still true to their principles: they built their own house from parts industrially made for other purposes such as factory buildings, boats or even airplanes. The house cost much less to build than average houses of its day and was erected in record time.

The Eames Modular House

Two years after moving into their own home, Charles and Ray had the opportunity to deliver on their factory-made housing idea when the Kwikset Lock Company, which wanted to enter this business, commissioned them to design a low-cost, prefabricated house for series production. They designed a system for modular houses made of components that could be manufactured in quantity and sold as a kit. The front façade was designed as a modular framework into which the door and panels of translucent and clear glass were fitted. In a 1951 editorial for the St. Louis Post Dispatch, Charles explained their approach: “The shell of the house is a simple structure consisting of a curved roof with flanges at the sides supported by posts. The walls can be wood and glass, or steel and glass, the amount of glass being optional according to taste, location and climatic conditions.”

The one-story structure had a curved roof supported by arc beams made from laminated plywood. The beams and other structural elements were to be left exposed. The open plan of the interior was divided by freestanding storage walls into a living and dining area, a kitchen, enclosed bathrooms and a bedroom. The feeling of space and comfort in the double-height main room was amplified by spots lighting the curved wooden ceiling. By not planning fixed rooms separated by floor to ceiling walls, the Eameses provided an architectural concept that is flexible and more spacious than the typical house. The Modular House is a system of individual, narrow “bays”, that allow many configurations, from two bays up to many, depending on the size required: For a couple, a two or three-bay Modular Home could work. A family of four may require a five-bay home.

The primary conditions are that the house can be built now – that is, with available resources—and that the materials used will not look shoddy after a little wear.” we approached the problem by determining how large an area could be shut off from the weather in a building that could be built for $8000. By making this the first consideration, rather than the number of cubicles—living room, bedrooms, bath, closets, etc. –usually thought of as basic, we found that we could double the area of a conventional house of the same cost.

Charles Eames

Eames Modular House, Architectural Model (Scale 1:12)

A new architectural scale model now recreates the Eames Modular House exactly as Charles and Ray envisioned it. At scale 1:12, the so-called “one-inch scale”, the model uses the same materials and construction principles that were specified in the original plans. It is based on a set of over 20 architectural drawings made by the Eames Office in 1951/1952 and now part of the Library of Congress. The historic drawings defined shape, materials and construction in detail—there are even plans for the heating systems, electrical installations, bathroom fittings and sewers. This comes as no surprise given the historic context: at the time the Eameses were ready to build the prototype house.

In 2021, the Eames Office researched and analyzed all available information about the house project before turning the historic two-dimensional drawings into a full three-dimensional CAD model, which then became the blueprint for an impressive scale model, executed by architectural modelmakers in Poland and Switzerland. The structure was executed exactly the way Charles and Ray wanted to build it in 1951. The model makers used a concrete base plate of the same quality and shape, they bent arc-beams from birch plywood, sidings from cedarwood, metal fittings, and window frames exactly to scale and based on the historic plans. The model’s roof lifts off to reveal the floorplan and interior structure.

The interiors were reconstructed using reference photos of a historic scale model built by the Eames Office in 1951. This long-lost model, executed in cardboard and wood, was primarily made to give a feeling of space and interior quality. Several photographs show the generous space of the central room, give an idea of scale with the help of miniature furniture and create a realistic atmosphere with miniature accessories and even miniature inhabitants cut out from black and white photographs. With the historic model not being archived or documented, its scale remained unclear in the beginning until a photograph of Charles’ head inside the model revealed that it was also created at scale 1:12.

The new scale model references many of their historic model’s furniture designs or props. Iconic Eames designs such as the ESU Storage Units or the Sofa Compact were custom-made at miniature scale and the model creates a realistic image of how a family could have lived in an Eames Modular House in the late 1950s. Some of the miniature scenes are based on the Eameses’ 1958 Revell Toy House for that purpose.

Models and model making were essential parts of the Eames process, so much so that in April 1975 Charles gave an entire speech on the subject called “An Architectural Model is An Information Device.” He talked about the many models the Eames Office had made of chairs, exhibitions, and entire buildings, and the films they produced as models of concepts, all as a necessary step before proceeding to finalize any design. Something Charles said in his conclusion to his speech seems to relate very well to this new architectural model: “With any working model, you get feedback. And you get your feedback while there’s still time to do something about it. That’s the important thing about models.”

The new scale model helps us understand all aspects of this early prefab home. Hopefully this will be a step towards realizing the Eames Modular House at full scale one day.

The model is currently displayed at “Eames Office: 80 Years of Design” at Isetan The Space in Shinjuku Tokyo, Japan, from November 5, 2021, through January 5, 2022. The multi-faceted exhibition explores the work of the Eames Office across three parts: influential experimentations in Art & Technology, groundbreaking innovations in Architecture & Interiors, and the joy and wonder brought to people of all ages through designs that encourage one to Play & Learn.

Materials: concrete, plywood, plexiglass (clear and opaque), rubber, brass, steel.

Size: 123 x 117 x 40 cm (W x L x H)

Weight: ca. 140 kg

Production: Eames Office, 2021