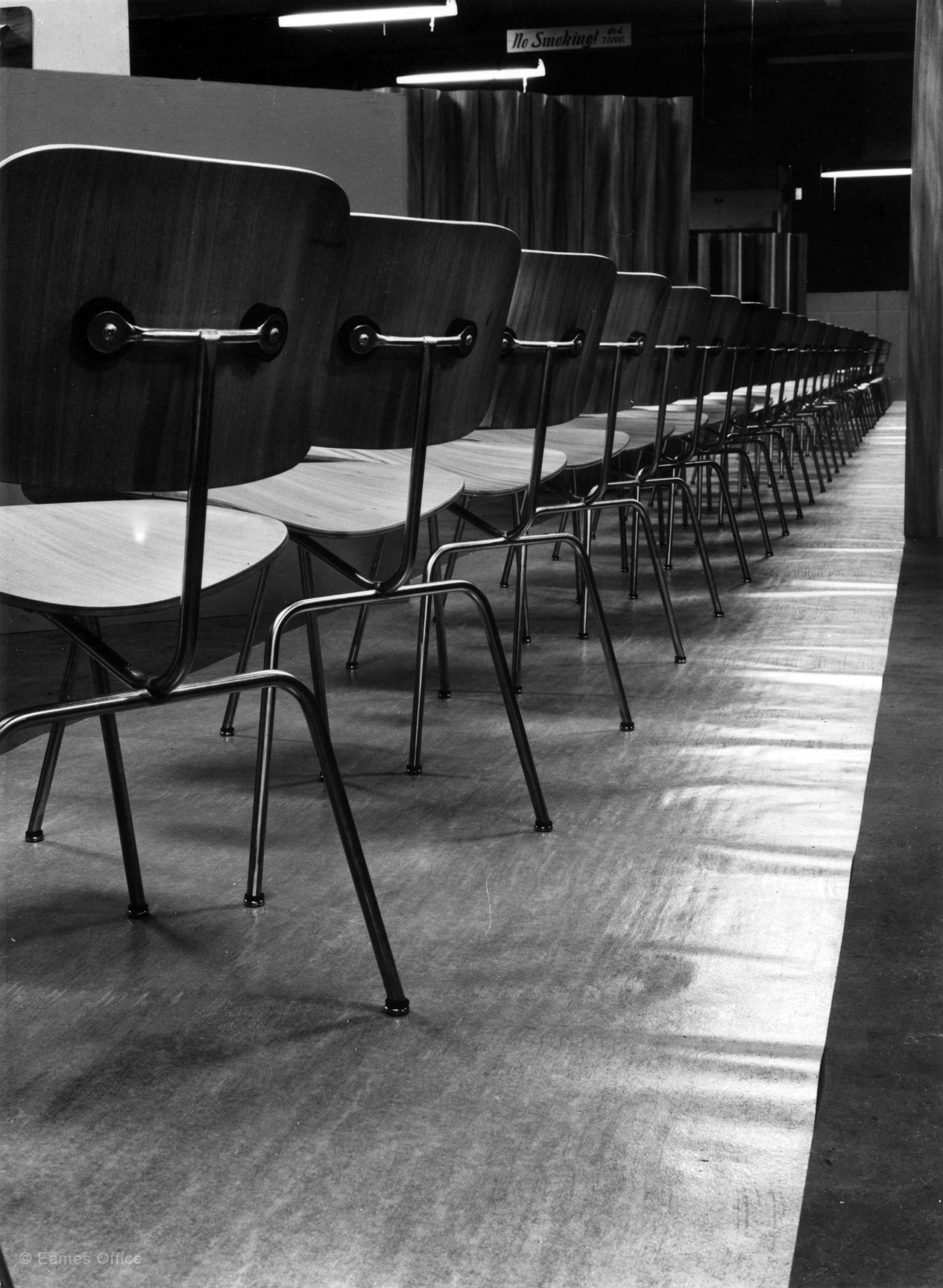

Eames DCM

The Eames DCM features sheets of premium face veneer on both sides of the seat and back. It uses two pieces of molded plywood and metal rods for support creating supreme body-cradling comfort. The gentle curves and comfort created from the molding process of a hard material established a foundation for future modern design. The DCM frame is much more delicate than the bent wood legs and frame of the DCW. Steel rod can do the job of wood, with less mass.

By 1945, when the Eames Molded Plywood Group was introduced to potential distribution partners, and 1946, when the Eames DCM and the rest of the group was introduced to the public in a rather grand way, at the Museum of Modern Art, Charles and Ray had many years of plywood experience under their belt. Charles had used plywood for the Kleinhans Auditorium, the Crow Island School chairs, and the Organic Design competition chairs. Charles and Ray co-designed the Eames leg splint, molded of plywood with the compound curves characteristic of what they then called the “Eames process,” which was patented.

The molded plywood furniture was sturdy, lightweight, and the parts were susceptible to mass production, using the “Eames process,” by which the actual sheets of plywood were formed at the same time as the compound curves were imposed. Using a homemade device, Charles and Ray called the “Kazaam” machine (referencing stage magicians, who put one object in a box and pull out a distinctly different one, Ala Kazaam!), perfected molding in their own residential apartment on Strathmore Avenue in West Los Angeles. The first plywood pieces got their shape from balloons, which Charles and Ray filled with air supplied by a bicycle pump!

One of the Eameses’ most inventive ideas was the application of shock mounts to furniture design. Previously employed only for industrial purposes, Charles and Ray were the first to adapt the technique to plywood chairs. They used thick rubber discs to reduce the shock between the wooden seat and back sections, providing strength, resiliency, and flexibility within the composition.

The Eames DCM is still manufactured today by Vitra and Herman Miller.